Phone Number

Email Address

Office Address

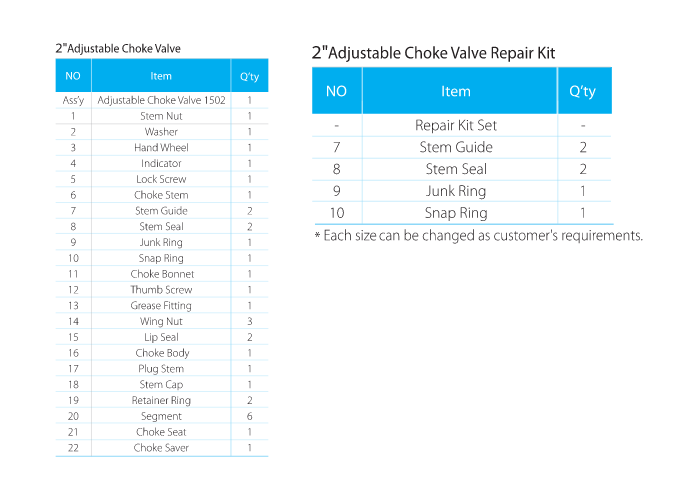

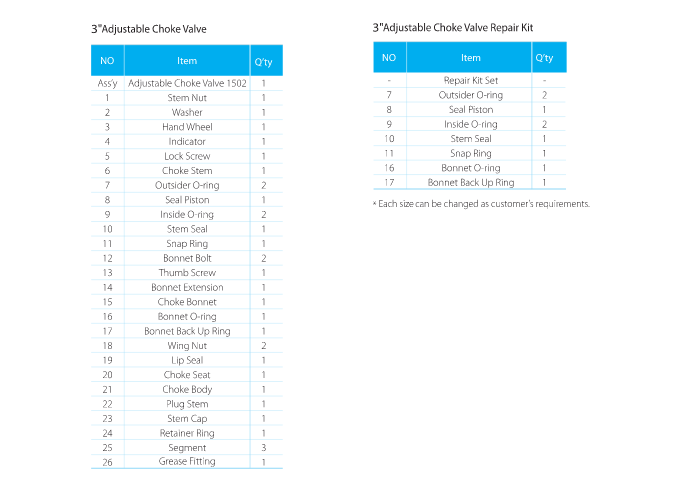

• 2" Fig 1502 MxF with 3/4" or 1" Orifice and 3" Fig 1502 MxF with 2" Orifice.

• Standard service is used up to 15,000psi and tested at 22,500psi

• H2S service is used up to 10,000psi and tested at 15,000psi

• Hammer Union End Connection

• Forged alloy steel body, stainless steel and tungsten carbide parts

• Parts are interchangeable with major brands

• Suiteeable for a broad range of applications including wellheads, well testing, stream injection, choke and kill manifolds and well clean operations, etc.

Features:

• Long life and low maintenance.

• Body to bonnet contact behind the O-ring seal eliminates bonnet seal extrusion.

• A locking device is set on stem.

• Ideal for many flow regulating services and easily convertable to a positive choke.

• The stem of adjustable choke are made of high strength alloy steel. The materials have the feature of abrasion resistance, erosion resistance and reliable serviceability.

• The valve and seat can be removed by hand, without special tools and without removal of the valve body from the line, by simply removing the bonnet.

Specifications:

• Basic Design and Test

• Working Pressure

• Main Nominal Size(in)

• Product Specification Level

• Performance Requirement Level

• Material Class

• End Connection

API-6A

2000, 3000, 5000, 10000, 15000, 20000 (Psi)

N60, N62, 1-13/16, 2-1/16, 2-9/16, 3-1/16, 3-1/8, 4-1/16

PSL1, PSL2, PSL3, PSL4

PR1, PR2

AA, BB, CC, DD, EE, FF

Flanged, Thread, Flanged and Thread

ANSI

400, 600, 900, 1500, 2500 (LB)

2, 2-1/2, 3, 4, 6, 8

PSL1, PSL2, PSL3, PSL4

PR1, PR2

AA, BB, CC, DD, EE, FF

Flanged, Weld

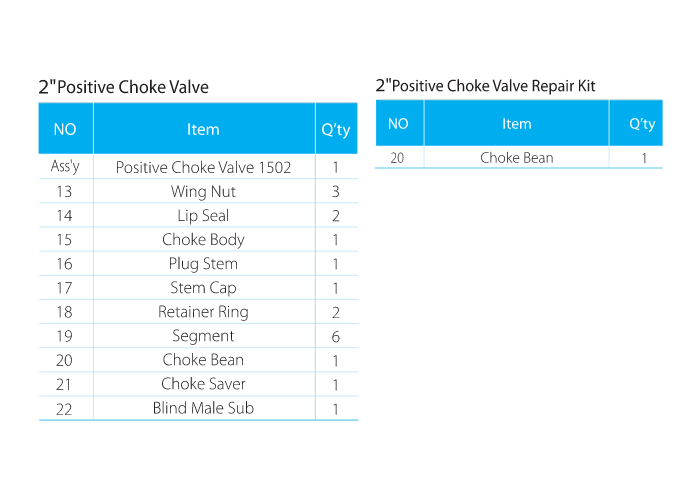

Features:

• Body to bonnet contact behind the O-ring seal eliminates bonnet seal extrusion.

• The bean of positive choke are made of ceramic or hard alloy steel. Both have the feature of abrasion resistance, erosion resistance and reliable serviceability.

• Flow bean chamfers are available from 2/64" to 64/64", in 1/64" increments for precise regulation of flow rate.

• The choke bean may be dismantled quickly for change of beans.

Specifications:

• Basic Design and Test

• Working Pressure (Psi)

• Main Nominal Size (in)

• Product Specification Level

• Performance Requirement Level

• Material Class

• End Connection

API-6A

2000, 3000, 5000, 10000, 15000, 20000

1-13/16, 2-1/16, 2-9/16, 3-1/16, 3-1/8, 4-1/16 PSL1, PSL2, PSL3, PSL4

PR1, PR2

AA, BB, CC, DD, EE, FF

Flanged, Thread, Flanged and Thread